- Description

- Specifications

- Documents

Features and Specifications

Vacuum Operated – Single PCU with Pump

Unit: bar

Vacuum Range: 30 to 1,000 mbar

Vacuum Range Increment: 10 mbar

Accuracy: +/- 0.015% of reading (+/- 0.008% optional)

Mass and PCU Materials of Construction:

Piston material: CeramicCylinder material: Martensitic steel

Coefficient of expansion: 11 ppm/ Celsius

Highlights

Piston-cylinder design provides stability and repeatability

Piston flotation indicator

High quality needle valves provide optimum control

Mounted spirit level and adjustable feet

Test station design with O-rings eliminates the need for PTFE tape or wrenches

Dual vacuum/pressure model:

Optional built-in hand pump for both pressure and vacuum generationNo Fine Inc. weights are available for this model

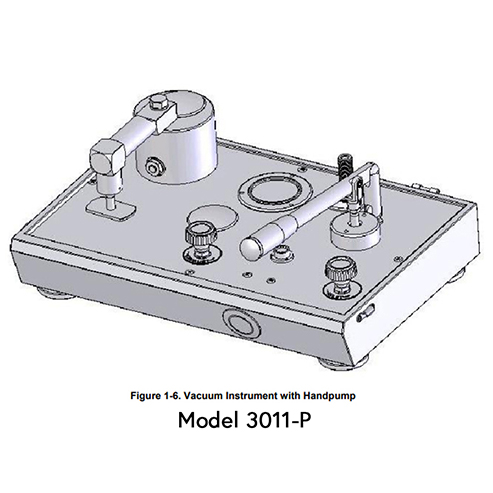

P3011-MBAR-P Overview

The P3011-MBAR-P Deadweight Tester (DWT) is a highly reliable and adaptable standard for measuring pressure, offering precise and uncontaminated pressure calibration. It's a high-performing device, specifically designed for gas operations, including vacuum calibration, thanks to its unique suspended piston design. The piston/cylinder assembly is manufactured to the highest standards with certified accuracies traceable to International Standards Laboratories such as the National Institute of Standards and Technology (NIST). These piston/cylinder type pneumatic standards provide excellent stability, repeatability and accuracy.

Vacuum and Dual Vacuum/Pressure Model

The P3011-MBAR-P features an optional built-in hand pump. The combined vacuum/pressure models like the P3011-MBAR-P are extremely versatile instruments providing vacuum through 500 psi (3.5 MPa) capacity in one unit. The hand pump can be installed to generate vacuum (90 %) through 300 psi (2 MPa).

When it comes to low gas pressures, the pressure is generated using a hand pump. Higher gas pressures (more than 2 MPa or 300 psi) require the use of an external source, such as a nitrogen bottle. Even when pumps are rated to higher pressures, users will normally find them difficult to use because of the forces involved. Generation of negative gauge, or vacuum, is similar in concept to positive pressure. For lower vacuum pressures with small volumes a built in hand pump will be sufficient. For larger volumes or higher vacuums, an external vacuum pump may be desirable.

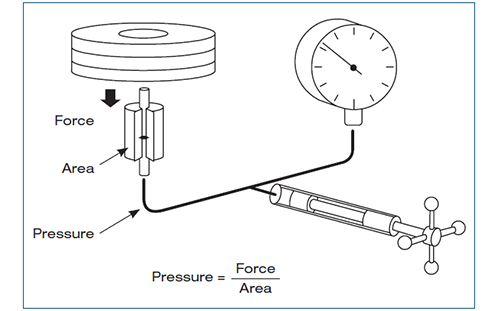

Operating Principle of a DWT

As the primary standard for pressure measurement, DWTs employ a well-established Piston-Gauge system. This system comprises a vertically positioned, precision-lapped Piston and Cylinder assembly. Accurately calibrated weight masses are loaded onto the piston, which ascends freely within its cylinder. These weights counterbalance the upward force generated by the system's pressure. Each weight is labeled with the tester's serial number and measures the pressure when placed on a correctly spinning and floating piston. The total pressure measured is the sum of the weights plus the piston weight carrier assembly. When the gas pressure within the system equals the combined downward force of the piston and weights, the piston and weights will float freely, indicating that the system is in equilibrium.

The design of a Piston/Cylinder Unit (PCU) incorporated into a deadweight tester allows for a minimal clearance gap between the piston and cylinder. This gap is necessary to let the gas flow between the components, creating a lubricating film and preventing direct metal contact.

P3000 Series Pneumatic Deadweight Testers

The P3000 Series high-performing gas-operated deadweight testers feature a design to improve accuracy and performance, increase reliability and simplify operation. These deadweight testers can be used to calibrate virtually any pressure sensing device, including transducers, transmitters, gauges or pressure switches.

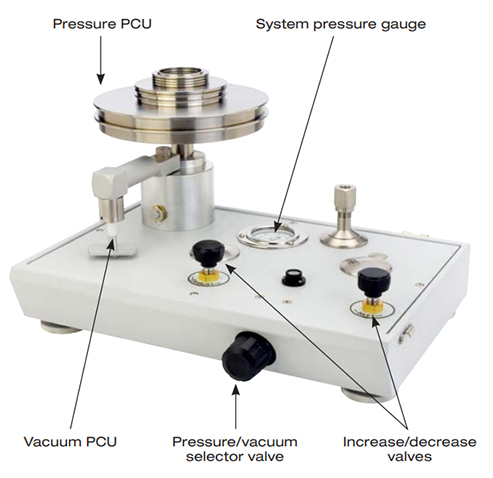

Instrument Base

There are four basic variations in the pneumatic offering; single pressure, single vacuum, dual vacuum and pressure, and oil-lubricated pneumatically driven high-pressure models. Pressure or vacuum is generated by an external source or an optional built-in hand pump (standard on the lower pressure models). The hand pump option is not available on instruments above 500 psi (3.5 MPa).

Categories of P3000 Models

There are many models in the P3000 product line, so for the purpose of this uncertainty analysis they are categorized as shown below.

*Full model names include variations depending on the nominal unit of measurement and inclusion of a built-in pressure pump.

Category | Range | Model* | |

|---|---|---|---|

Vacuum | -3 to -100 kPa (-30 to -1000 mbar, -1 to -30 InHg) | P3011, P3022 (VAC), P3023 (VAC), P3024 (VAC) | |

Low Pressure Gas | Positive gauge ranges up to 200 kPa (up to 30 psi) | P3012, P3013, P3023 (HP) | |

Medium Pressure Gas | 1000 and 3500 kPa (150 and 500 psi) | P3014, P3015, P3024 (HP) | |

High Pressure Gas | 7000 and 14000 kPa (1000 and 2000 psi) | P3031, P3032 | |

Low Pressure Oil | 3.5 and 14 MPa (500 and 2000 psi) | P3111, P3112, P3123(LP), P3124(LP), P3125(LP) | |

Medium Pressure Oil | 35 and 70 MPa (5000 and 10000 psi) | P3113, P3114, P3123(HP), P3124(HP) | |

High Pressure Oil | 110 MPa and 140 (16000 and 20000 psi) | P3115, P3116, P3125(HP) | |

Very High Pressure Oil | l 200, 260 and 400 MPa (30000, 40000 and 60000 psi) | P3830, P3840, P3860 | |

Low Pressure Water | 3.5 MPa (500 psi) | P3211, P3223(LP), P3224(LP) | |

Medium Pressure Water | 35 and 70 MPa (5000 and 10000 psi) | P3213, P3214, P3223(HP), P3224(HP) | |

Built-in Hand Pumps (-P models: indicates built-in pump optional)

Pressure or vacuum is generated by an external source or a hand pump (standard on the lower pressure models). The hand pump option is not available on instruments above 500 psi (3.5 MPa).

Pressure mode: Max pressure 300 psi (2 MPa)

Vacuum mode: To 90 % vacuum

Piston/Cylinder Assemblies

The piston/cylinder assembly is the heart of each deadweight tester. They are manufactured from materials that provide stability, durability, and low thermal coefficients and distortion. Fluke's experience and knowledge of piston/cylinder production and calibration ensures the precision and performance required for today’s demanding calibration requirements.

Masses

Standard weight masses are series 3 nonmagnetic austenitic stainless steel. Each mass is marked with the serial number of the instrument and the nominal pressure value relative to the high- or low-pressure piston, when applicable. Vacuum weights and the optional fractional weights are stainless steel and/or solution heat treated aluminum.

Minimum Standard Weight Increments

P3012, P3022 Pressure: 1 inH2O, (5 mbar, 0.5 kPa)

P3013, P3023 Pressure: 2 inH2O, (10 mbar, 1 kPa)

P3014, P3015, P3025 Pressure: 1 psi, (0.1bar, 10 kPa)

P3031, P3032: 1 psi, (0.1bar, 10 kPa)

P3011, P3022, P3023, P3025 Vacuum: 0.2 inHg (10 mbar, 1 kPa)

Gravity

For the P3000 Series Deadweight Testers (DWT), customers have two choices. The deadweight tester can be provided matched to standard gravity (9.80665 m/s2 ) and the customer can utilize software (such as Fluke Calibration PressCal) to account for the acceleration of local gravity. Or, the deadweight tester can be provided matched to the local gravity value supplied by the customer. Gravity varies slightly from one location to another. This has an impact on the nominal pressure increments of a deadweight tester. To overcome this issue, at the time of manufacture Fluke Calibration trims the weights to produce the correct nominal pressures at your location. If unspecified, instruments will be calibrated to standard gravity.

Gas Supply

Gas operated (pneumatic) deadweight testers provide a proven, traceable, clean, and easy way for checking accuracy of pressure gauges and transfer standards. All P3000 instruments are fitted with a 1/4 inch NPT female external supply port for connection to the gas supply source. A compressed gas bottle (nitrogen or dry air) fitted with a pressure regulator is recommended. Ten percent above the maximum pressure is required. A built-in hand pump is available on some models to generate pressures to 300 psi (2 MPa).

For vacuum requirements, an external vacuum pump can be connected to the 1/4 inch port. The built-in hand pump will also generate up to 90 % vacuum.

PressCal Software

PressCal software is a Windows-based software program that allows users to easily apply all necessary corrections (e.g. local gravity, temperature, pressure head, etc.) to enhance the deadweight tester performance. Calibration details are then stored and/or used to automatically create a calibration certificate. The use of PressCal allows for an improved accuracy of 0.008 %. It will permit calibration in any of 12 different pressure units, using the existing weight set.

What's in the Box

P3011-MBAR-P Deadweight Tester Vacuum and Dual Vacuum/Pressure Model

Built-in pump optional

Series 3 nonmagnetic austenitic stainless steel masses

Vacuum weights

Detachable lid

Accredited calibration certificate

Adaptors

Rugged case